- Elevated to 15’ (4.5 m) above grade to protect against storm surge flooding

- Supplied with flowing filtered seawater or freshwater

- Able to generate directional waves combined with direct wind forcing

- Scaling allows for modeling a category 5 hurricane

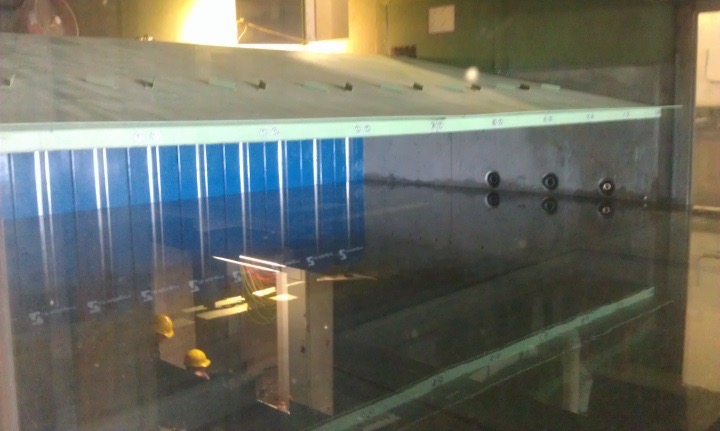

- Constructed of acrylic material

- Innovative optical measurements and flow visualization

- Total dimensions: 23-m long x 6-m wide x 2-m high

- Sloping beach with a 1-m horizontal section

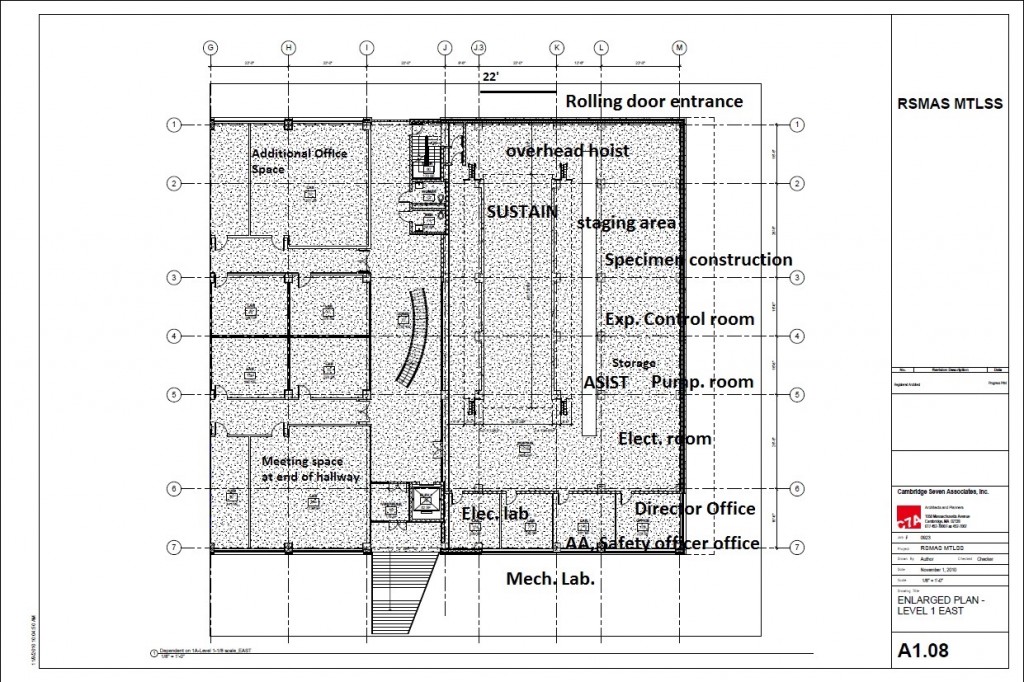

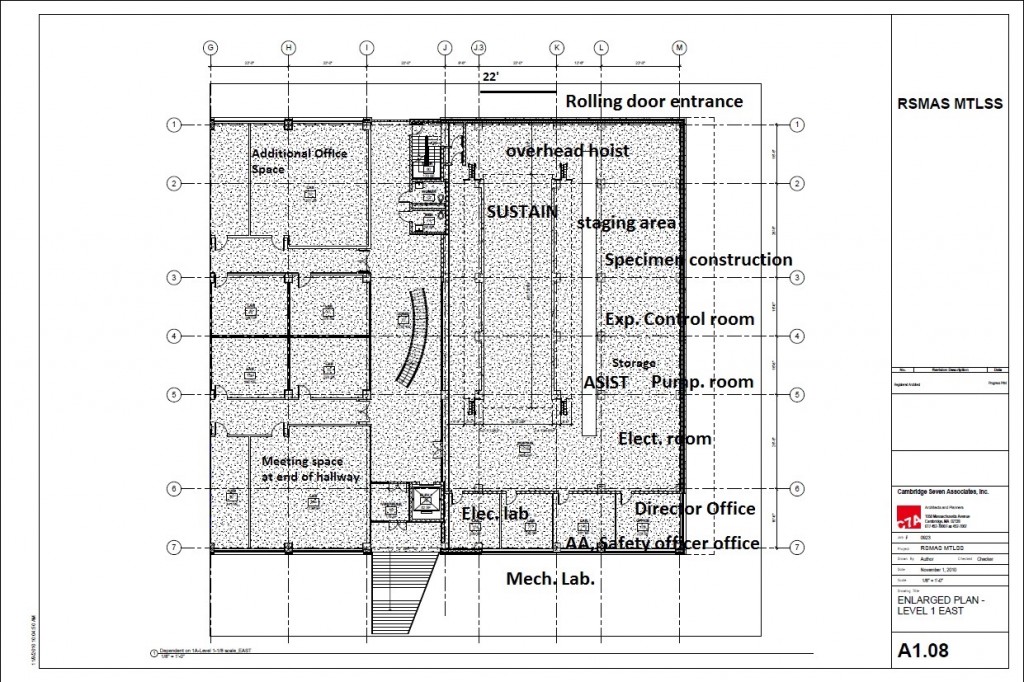

- Electrical and computer laboratories

- Specimen fabrication shop

- Roll-up entrance door and overhead hoist for large-scale test and monitoring equipment

Note: A first generation Air-Sea Interaction Saltwater Tank (ASIST), size 15x1x1m, is available for smaller-scale studies.

Figure 2. 1st floor plan of the SUSTAIN laboratory, with scale as shown 22’ between largest pile spacing. The SUSTAIN occupies all space to the right of the exit stairways as shown. It includes 2 offices and 2 lab spaces.

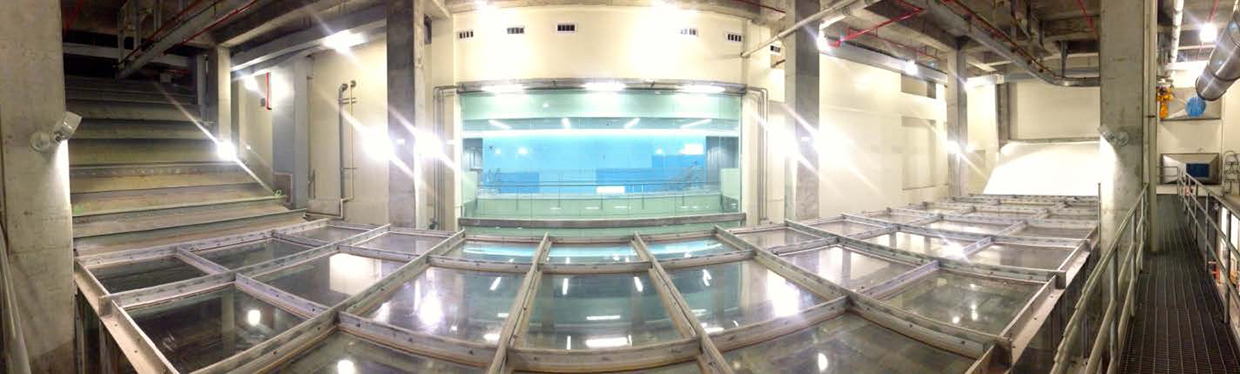

Figure 4. Panoramic view over the top of the SUSTAIN looking toward lobby, inlet and outlet ductwork is visible to the left and right respectively. Beam spacing on tank is 2-m crosswise x 1.8 m lengthwise.

Figure 4. Panoramic view over the top of the SUSTAIN looking toward lobby, inlet and outlet ductwork is visible to the left and right respectively. Beam spacing on tank is 2-m crosswise x 1.8 m lengthwise.